High-Accuracy Tactile Measurement

Our Coordinate Measuring Machine (CMM) provides highly accurate tactile measurements for dimensional inspection and verification of your parts. Utilizing precision probes, we can meticulously measure complex geometries, ensuring adherence to tight tolerances and specifications. This service is ideal for detailed analysis, first article inspection, and comprehensive quality control.

Precision Optical Measurement

Our MicroVu optical measurement machine offers non-contact, high-resolution dimensional inspection. Utilizing advanced optics and image processing, we can quickly and accurately measure intricate features and small components without physical contact. This method is particularly suitable for delicate parts, complex shapes, and high-volume inspection where speed and precision are critical.

Those machines are equipped with contact probes and confocal sensors.

High-Accuracy Optical Measurement for Shafts

Our Sylvac S25T optical measuring system provides rapid and highly accurate, non-contact measurement of cylindrical parts and shafts. This advanced technology allows for the precise determination of critical dimensions such as diameter, length, runout, concentricity, and thread parameters. The non-contact nature of the measurement is ideal for delicate or finished parts, ensuring no damage occurs during inspection. The Sylvac S25T enables efficient quality control and detailed analysis of your cylindrical components.

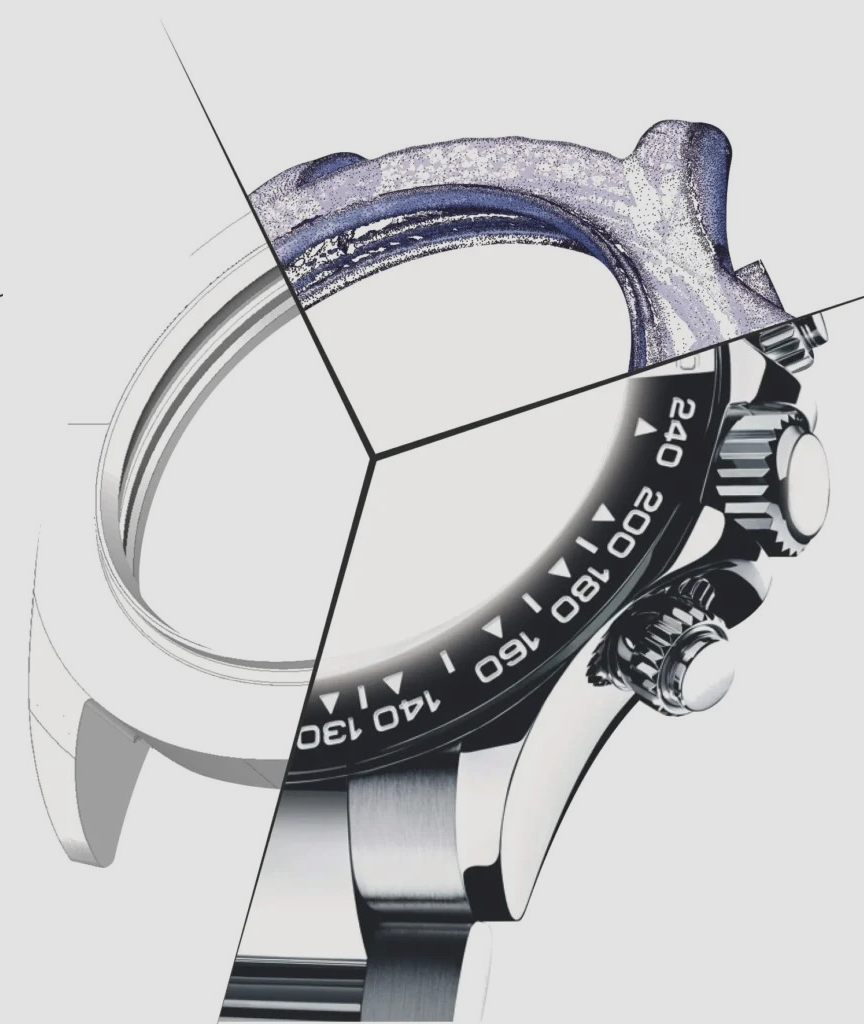

High-Precision 3D Scanning for Analysis and Quality Control

At Steen Laser Survey, we employ a high-precision 3D scanner (up to 20µm) to digitize your industrial parts. Direct comparison with the CAD file offers you a clear visualization of deformations and non-conformities, thereby helping you reduce defect-related costs and improve the quality of your products.

We can scan parts of all sizes, from 4 cm to 4 meters, with consistent precision.

From Point Cloud to CAD Model: Reverse Engineering

Our reverse engineering services utilize the powerful combination of SolidWorks CAD software and the QuickSurface plugin to create accurate and editable 3D CAD models from scanned data (point clouds or mesh files). This process allows us to reconstruct the digital representation of existing physical parts, even without original design files. Whether for design replication, modification, or analysis, our expertise in reverse engineering provides a streamlined and efficient pathway to obtaining precise 3D models tailored to your needs.